Sasha Diaries #3: A Visit to Jasper Hill

“I can’t remember a time when I’ve done so much hard work and had such a good time.” This is what my husband Michael said to me on our way home from Jasper Hill Farm. He digs cheese, a lot, but he doesn’t work in cheese and we went to visit the farm on a weekend when half the farm (2 people) was on vacation. There was no shortage of work to be done. Jasper Hill Farm is in Greensboro Vermont, the far reaches of the Northeast Kingdom. It is undeniably one of the most beautiful places in the world but that in and of itself wouldn’t be enough to make all the sweat, sore muscles and bug bites seem so completely worth the trip- Michael’s statement is a tribute to the people of Jasper Hill Farm. They are dedicated, smart and patient but most importantly they are welcoming and so much fun- especially their newest addition, Angie and Mateo’s son Reed, who at only six months is already showing potential for the strongest man in the world competition.  I had been to Jasper Hill once before almost a year ago now with my cheese friend Tyler. Ever since we departed that first time we’ve been scheming on how to get back. This most recent trip did not disappoint. The farm is run by two brothers and their wives: Mateo and Angie, and Andy and Victoria. The weekend we visited Andy and Victoria were on a two-week vacation. Regardless of the fact that it is summer and vacation time for most people the cows have to be milked twice a day, seven days a week and cheese is made every day (365 days a year). Then there are also the big picture things that have to be worked on: beginning to build up a store of hay in the upper floor of the barn to supplement the cows grass diet during the months when there is grass to eat and to fully feed them in the winter when the grass is gone, or knocking down the manure pile. And if you ride the crazy train like the Keehler brothers you also plan big hairy projects like adding a wrap around deck to the house you built yourselves and throwing up a new barn later this summer.

I had been to Jasper Hill once before almost a year ago now with my cheese friend Tyler. Ever since we departed that first time we’ve been scheming on how to get back. This most recent trip did not disappoint. The farm is run by two brothers and their wives: Mateo and Angie, and Andy and Victoria. The weekend we visited Andy and Victoria were on a two-week vacation. Regardless of the fact that it is summer and vacation time for most people the cows have to be milked twice a day, seven days a week and cheese is made every day (365 days a year). Then there are also the big picture things that have to be worked on: beginning to build up a store of hay in the upper floor of the barn to supplement the cows grass diet during the months when there is grass to eat and to fully feed them in the winter when the grass is gone, or knocking down the manure pile. And if you ride the crazy train like the Keehler brothers you also plan big hairy projects like adding a wrap around deck to the house you built yourselves and throwing up a new barn later this summer.

We were there for two and a half days and if I tried to give you all the details of what we did in one blog entry it would be too much. So I will summarize for now and rest assured that there will be posts soon to follow covering the details of the making and maturing of each cheese we assisted with.

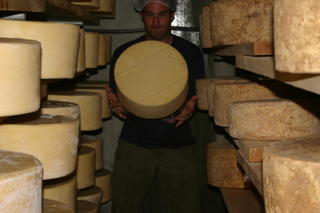

The three of us- Tyler, Michael and I- pitched in all over the place- the cellar, the barn, and of course, cheese making. Jasper Hill makes five completely different cheeses; soft ripened Constant Bliss, Creamy Blue Bayley Hazen, larger and slightly drier Bartlett Blue, Leicester-style Aspenhurst, and washed-rind Winnemere. The two staples are Bayley Hazen and Constant Bliss and assisted with a batch of each of those and then were also lucky enough to get to help with a batch of Aspenhurst. We also got to participate in a new-ish activity at JHF: clothbound Cabot cheddar flipping. These Cabots are 40 lb. wheels made by Cabot Creamery (also in VT, a much larger dairy farm). Cabot produces the wheels especially for JHF from a closed herd of approximately 300 cows. They are delivered to JHF when days old and then are wrapped in cheesecloth and rubbed down with lard. Jasper Hill is keeping these wheels for 9-14 months. They had recently received, bandaged and lubed, 120 wheels which need to be flipped once a day for the first 30 days and then once per week for the remainder of their stay.

Mateo gave us a Cabot flipping demo- he took a wheel, laid it flat across his palms and with ease tossed it up so that it flipped and landed opposite side down in his hands- all in one seamless motion and was lofted back onto its spot on the shelf.

I knew better than to try this with my pipe cleaner arms but Michael and Tyler shrugged and boldly tossed their wheels up- easy as pie- until 40 lbs came back to land on their hands…knees, or ankles but luckily not the floor. Note: do not make jokes while flipping the Cabots- this will only lead to lard stained pants and bruising.

I knew better than to try this with my pipe cleaner arms but Michael and Tyler shrugged and boldly tossed their wheels up- easy as pie- until 40 lbs came back to land on their hands…knees, or ankles but luckily not the floor. Note: do not make jokes while flipping the Cabots- this will only lead to lard stained pants and bruising.  We also stacked new bales of hay in the barn- the sweating alone made it a somewhat transformative experience. One of the best things was riding out to one of the pastures to check on the adolescent cows and make sure they hadn’t escaped from their paddock. It will never stop being funny to me that cows come when you call them- never. Mateo yelped something out and 14 mid size cows all started galloping after the ATV. Then there was the visit to the lake, the perfect antidote to uncontrollable sweating and scratched up arms n’ legs. And before partaking in the most strenuous cheese making day (Aspenhurst) we tasted all the wine Michael had selected and brought (he is a sommelier) to find great pairings for the Jasper Hill cheese collection.

We also stacked new bales of hay in the barn- the sweating alone made it a somewhat transformative experience. One of the best things was riding out to one of the pastures to check on the adolescent cows and make sure they hadn’t escaped from their paddock. It will never stop being funny to me that cows come when you call them- never. Mateo yelped something out and 14 mid size cows all started galloping after the ATV. Then there was the visit to the lake, the perfect antidote to uncontrollable sweating and scratched up arms n’ legs. And before partaking in the most strenuous cheese making day (Aspenhurst) we tasted all the wine Michael had selected and brought (he is a sommelier) to find great pairings for the Jasper Hill cheese collection.  All in all I found myself much more aware of all that there is to be done on the farm. I’m sure that this was partly because without Andy and Victoria there was simply more to do but I don’t think that’s the only reason. I’ve been thinking a lot recently about one of the most common criticisms I hear about American farmstead and artisan cheeses: They are so expensive! I have met enough cheese makers in the US to understand that it is not what one would refer to as a lucrative occupation. This doesn’t mean that its’ not possible to make money at it but its not at all easy either. So on this trip, as I was ladling Constant Bliss, fluffing Aspenhurst curd (this sounds so much easier than it actually is), piercing Bayley Hazens, or lugging bales of hay through the 100+ degree heat in the barn, I was constantly thinking about how one would calculate the true value of the products made at Jasper Hill. After participating in not only the cheese making and maturing work but also all the things that have to happen on the farm to have healthy animals producing calves and thus milk, I think that a piece of Constant Bliss for $8.99 or pound of Bayley Hazen for $16.99 at the Murrays cheese counter is quite literally a bargain.

All in all I found myself much more aware of all that there is to be done on the farm. I’m sure that this was partly because without Andy and Victoria there was simply more to do but I don’t think that’s the only reason. I’ve been thinking a lot recently about one of the most common criticisms I hear about American farmstead and artisan cheeses: They are so expensive! I have met enough cheese makers in the US to understand that it is not what one would refer to as a lucrative occupation. This doesn’t mean that its’ not possible to make money at it but its not at all easy either. So on this trip, as I was ladling Constant Bliss, fluffing Aspenhurst curd (this sounds so much easier than it actually is), piercing Bayley Hazens, or lugging bales of hay through the 100+ degree heat in the barn, I was constantly thinking about how one would calculate the true value of the products made at Jasper Hill. After participating in not only the cheese making and maturing work but also all the things that have to happen on the farm to have healthy animals producing calves and thus milk, I think that a piece of Constant Bliss for $8.99 or pound of Bayley Hazen for $16.99 at the Murrays cheese counter is quite literally a bargain.

I hope that you all will tune in for future entries on these cheeses to help you understand the care that is taken to produce them- or better yet- that you’ll come in and taste them!

<< Home